Reliability solutions to give you the cutting edge

Remote Condition Monitoring

Our Remote Condition Monitoring (RCM) solutions allow us to keep track of your critical assets in real time, no matter where they are. By using smart sensors and cloud-based analytics, we can detect early signs of wear, misalignment, or imbalance before they turn into costly failures.

Benefits:

Continuous 24/7 monitoring of your equipment

Early detection of potential failures

Reduced downtime and maintenance costs

Data-driven decision-making for maintenance planning

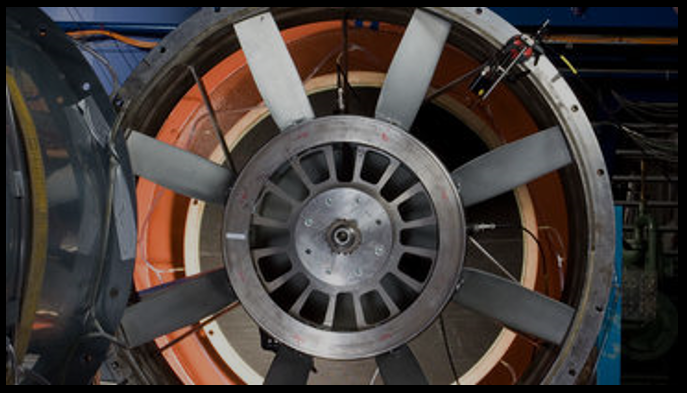

Vibration Analysis

Vibration Analysis is one of the most effective tools for identifying machine health issues. By measuring vibration levels and patterns, we can pinpoint problems such as bearing defects, misalignment, imbalance, or mechanical looseness—long before they lead to a breakdown.

What it helps detect:

Bearing wear and lubrication issues

Gearbox and coupling problems

Misalignment and imbalance

Structural looseness

Benefits:

Extends equipment life

Prevents unplanned shutdowns

Improves safety and reliability

Field Balancing

Improve machine reliability and reduce wear on machine components and running costs. Unbalanced rotating equipment can cause excessive vibration, premature wear, and costly damage. Our Field Balancing service corrects imbalance directly on-site, without the need to dismantle your machine.

Benefits

Reduced vibration and noise

Increased bearing and seal life

Minimized downtime (no need for disassembly)

Lower operating costs

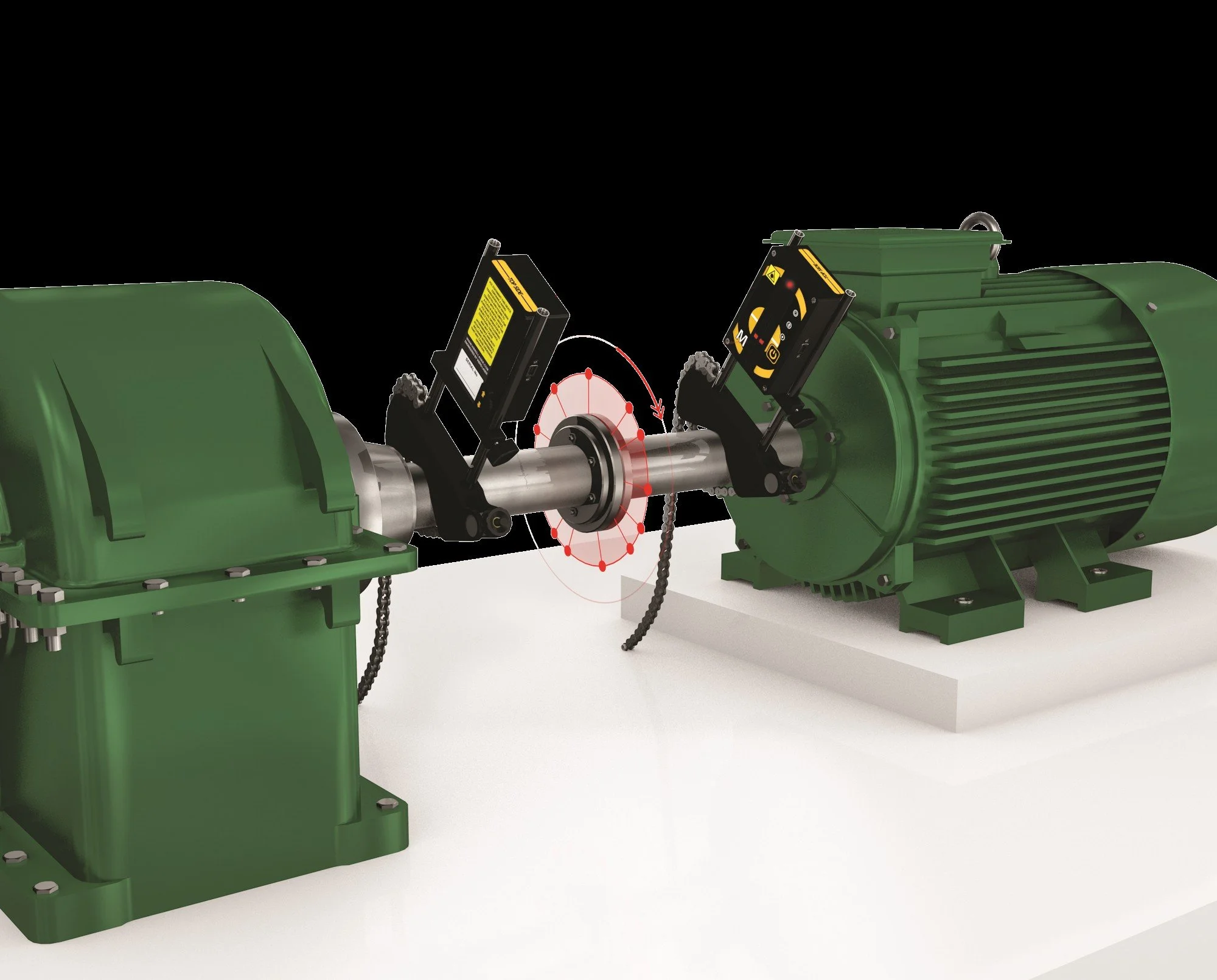

Shaft Alignment

Precision shaft alignment with micrometer accuracy to reduce unwanted wear and damage. Even the slightest shaft misalignment can cause serious wear and energy loss in rotating machinery. Our Laser Shaft Alignment service ensures that coupled machines are aligned with pinpoint accuracy.

Benefits

Extended machine life

Reduced energy consumption

Less vibration and heat generation

Faster, more accurate alignment compared to traditional methods

Oil Sampling & Analysis

Our Oil Sampling & Analysis service helps detect early signs of wear, contamination, or lubricant breakdown before they lead to costly repairs.

What we check

Wear particles from bearings, gears, and other components

Water, dirt, or other contaminants

Oil degradation

Lubrication effectiveness

Benefits:

Early detection of internal wear and potential failures

Optimized oil change intervals (no more unnecessary oil replacements)

Extended equipment and lubricant life

Reduced downtime and repair costs